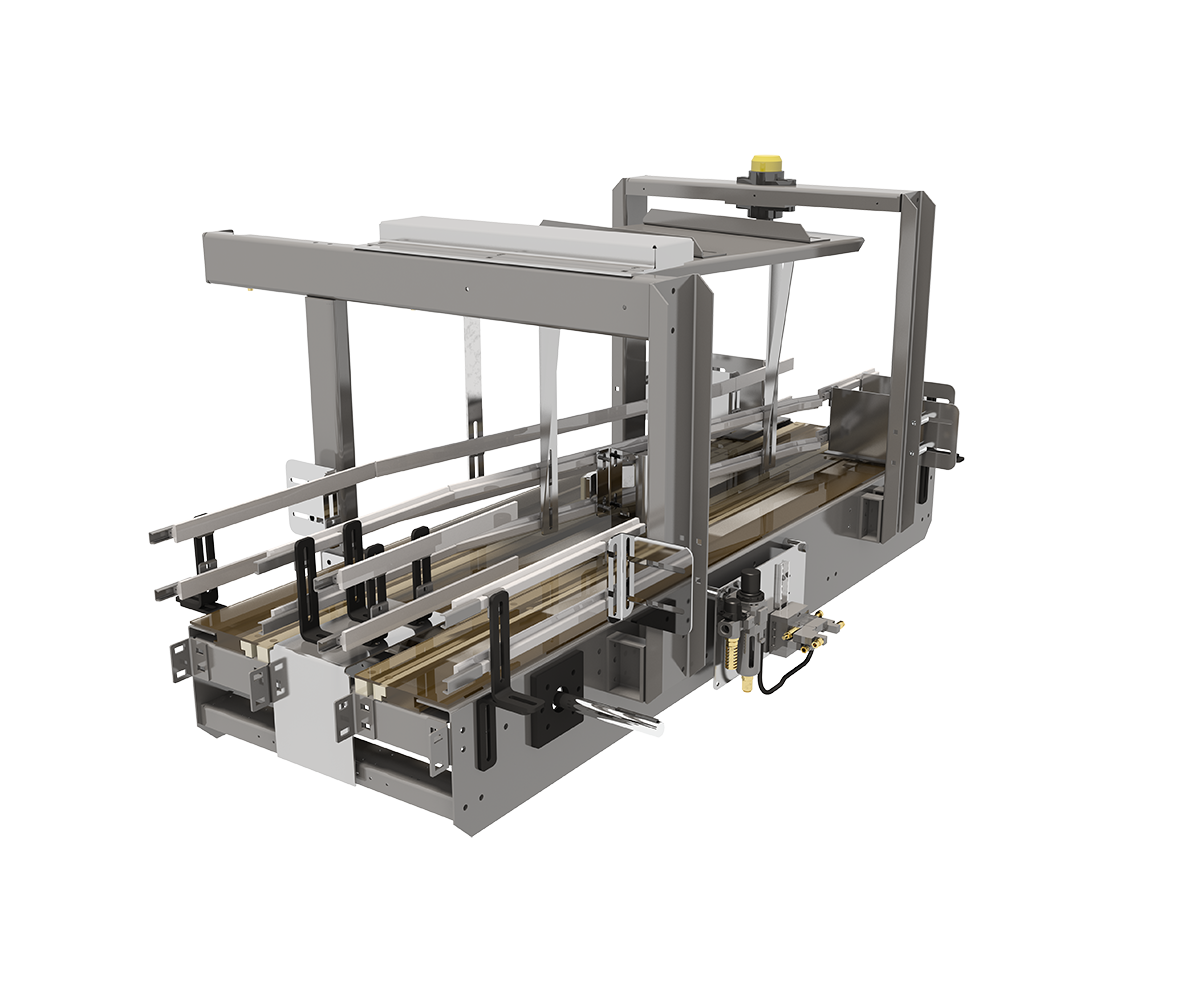

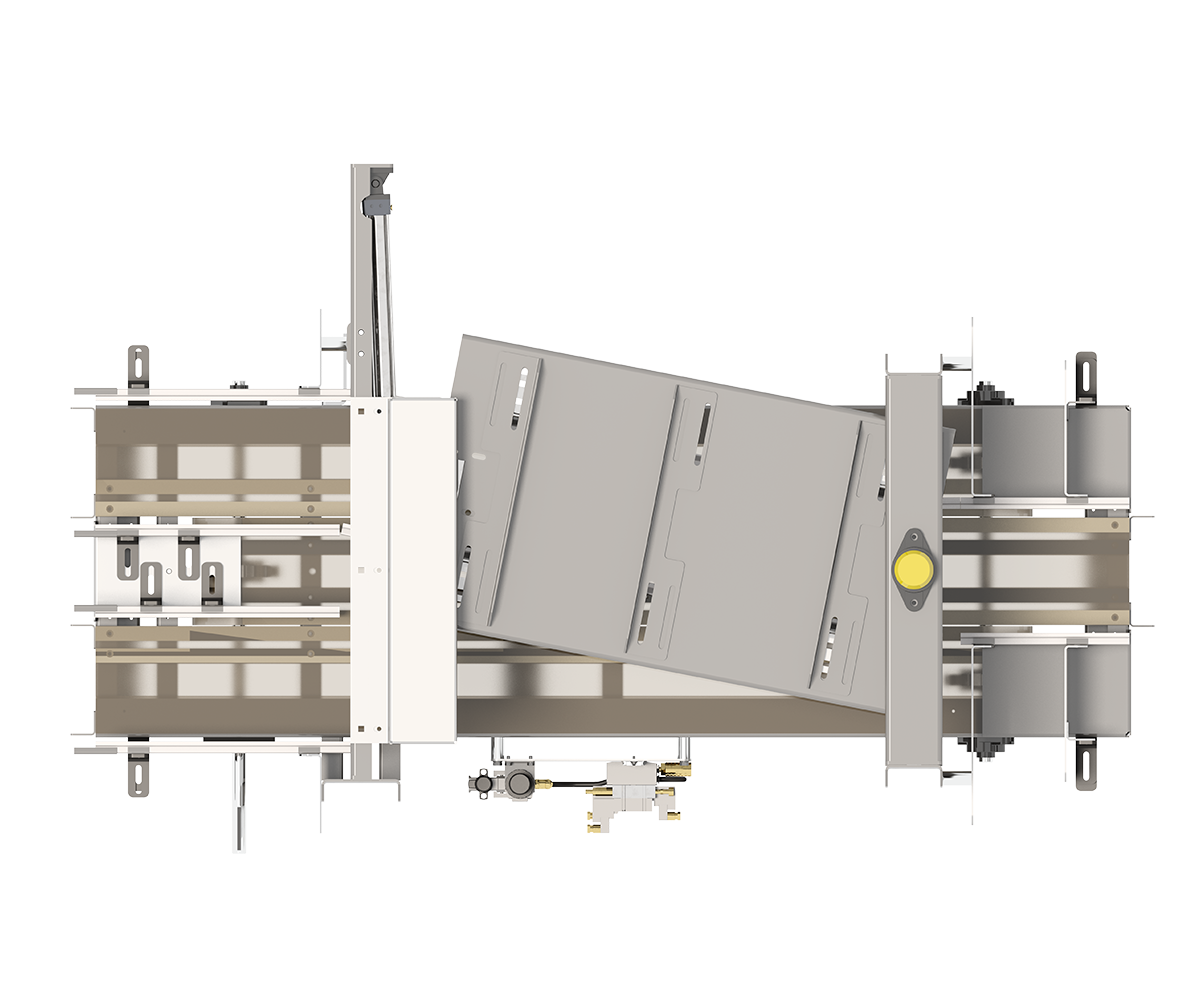

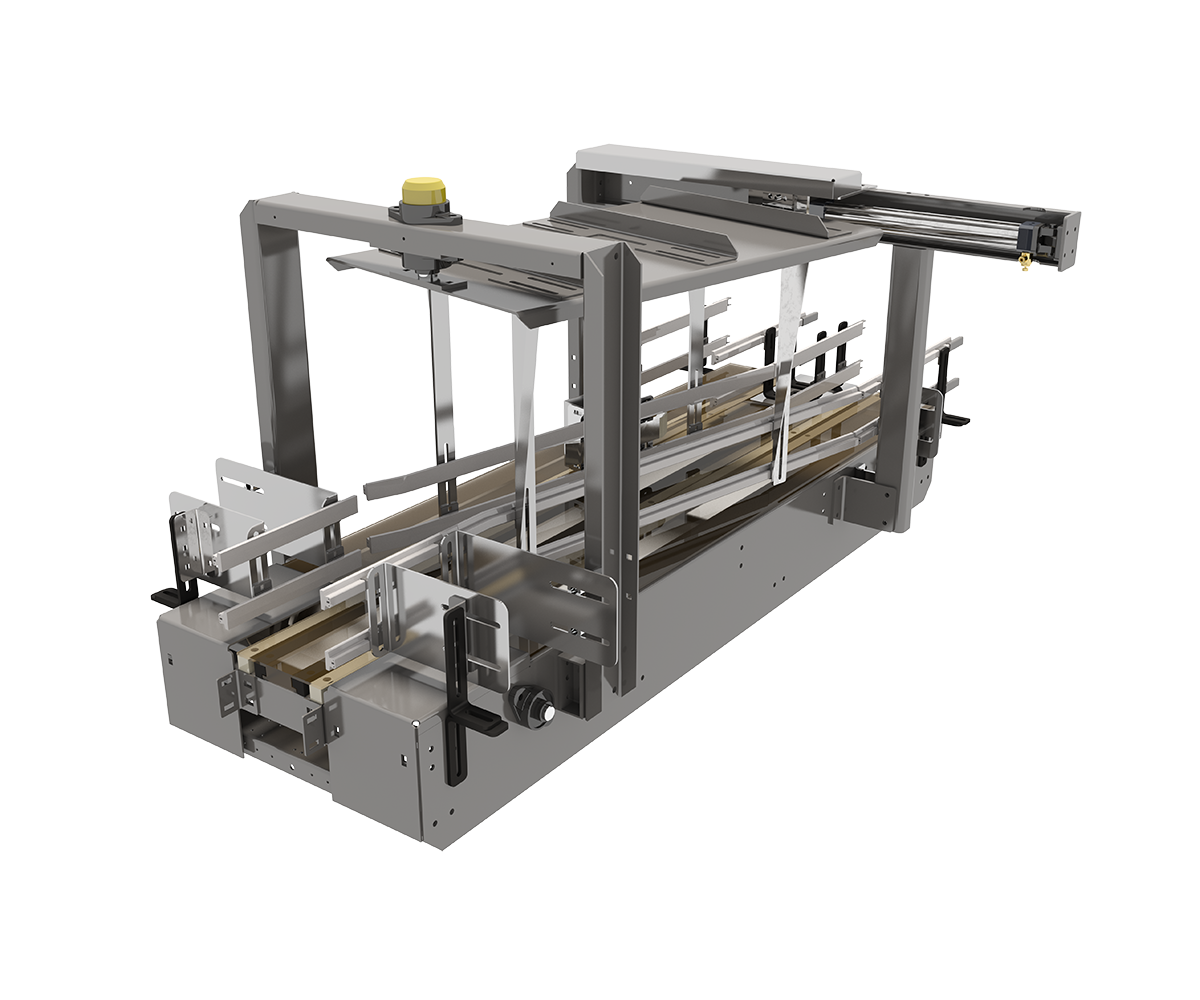

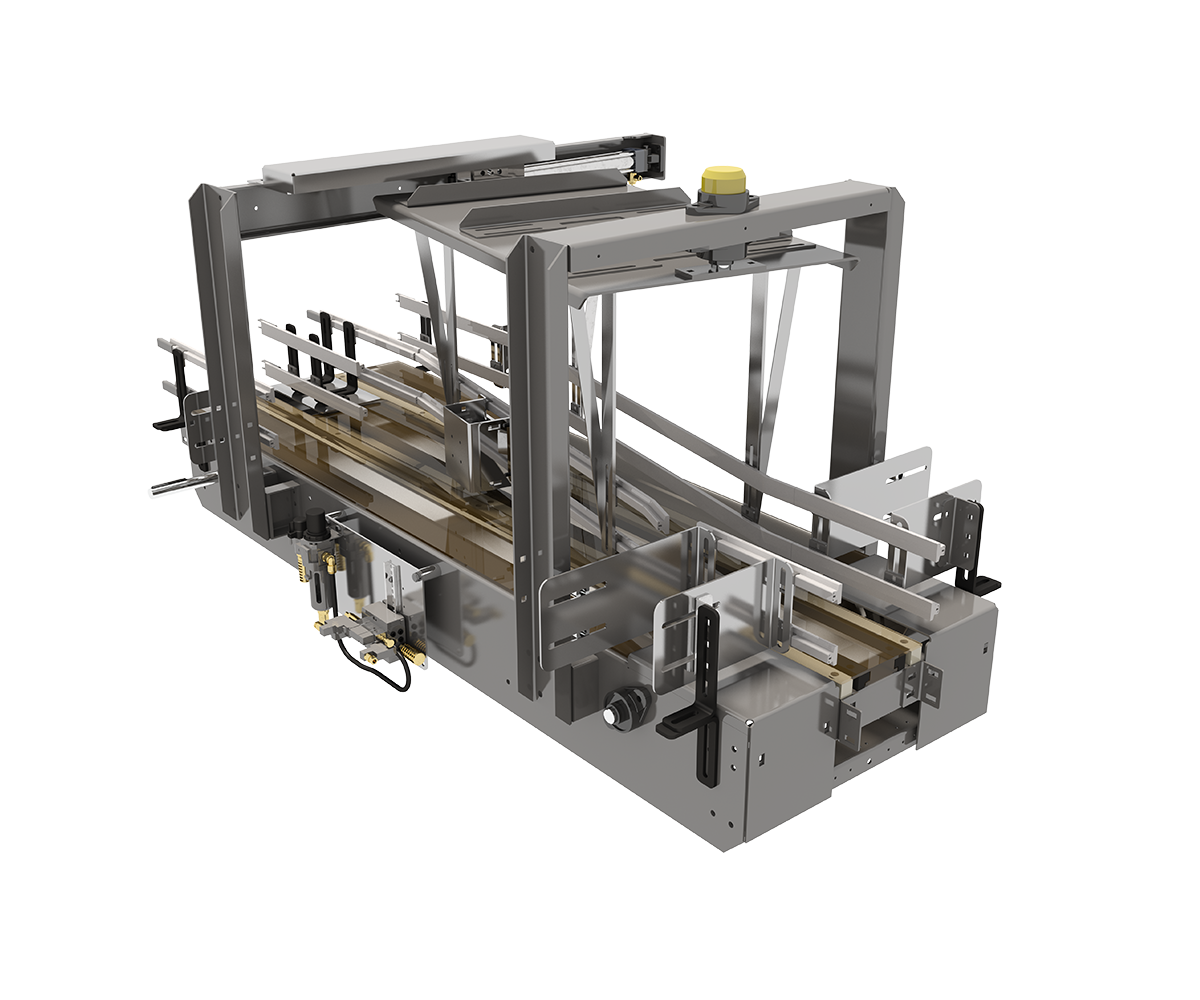

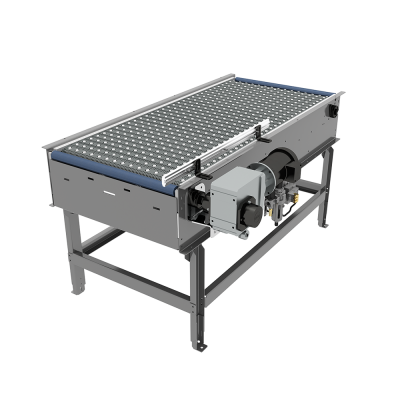

Conveyor Clamp & Shift Laner

Our Clamp & Shift Laner improves line efficiency by accurately managing product flow and laning products between processes. The system uses a clamp to stop product flow until the desired number of products have been accumulated. The clamp releases the lane of products to their designated downstream process.

- Function: Merge products to match downstream conditions with ease

- Applications: Most commonly used to divide one or more infeed lanes to several evenly balanced discharge lanes

- Motor Options: Available in manual, pneumatic, motor or servo drive operations

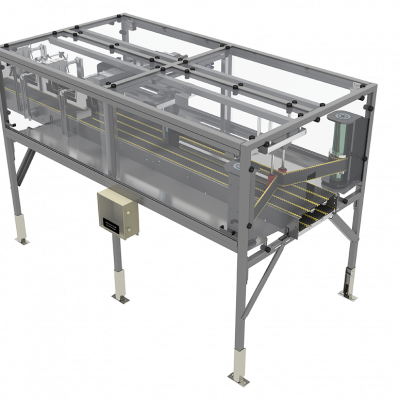

- Value-Add: Add available safety options, such as perimeter guarding with lockable access doors

MACHINE SPECIFICATIONS

End Product Details

Type:

Bottles, Boxes, Cans, Pucks

Shape:

Non-Round, Round

Fill:

Empty, Full

Material:

Aluminum, Composite Product, Corrugated, Glass, Poly Wrap, Steel

General Design

Modular:

Yes

Frame:

Open Top

Material:

Painted Steel, Stainless Steel

Return:

Roller, Serpentine

Wearstrip

Type:

UHMW

Motor/Drive

Type:

Standard Duty Motor, Wash Down, Stainless Steel Wash Down

Type 2:

Gear Motor, Inverter Duty, Servo

Style:

Flange Mounted, Shaft Mounted

Supports

Material:

Stainless Steel, Painted Steel

Construction:

Square Tube, Welded H Style, Formed Channel

Adjustment Type:

Per Customer Specification

Adjustment Increment:

3″

Warranty

Warranty:

1 Year Warranty